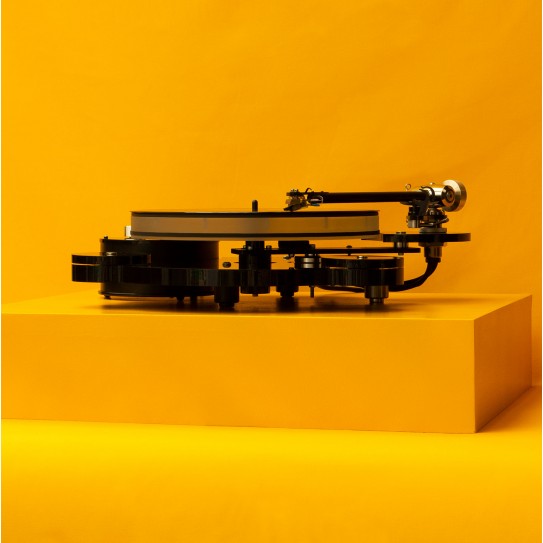

DC Motor kit for Turntable

- BrandsOrigin Live Turntables -Tonearms

- Product Code: DC Motor kit

- Availability: 1

500.00€

Available Options

The Motor Kit upgrade is applicable if:

You have a noisy or broken turntable motor Your motor has a faulty power supply You want to upgrade the performance of your turntable

Included in all DC Motor Kits:

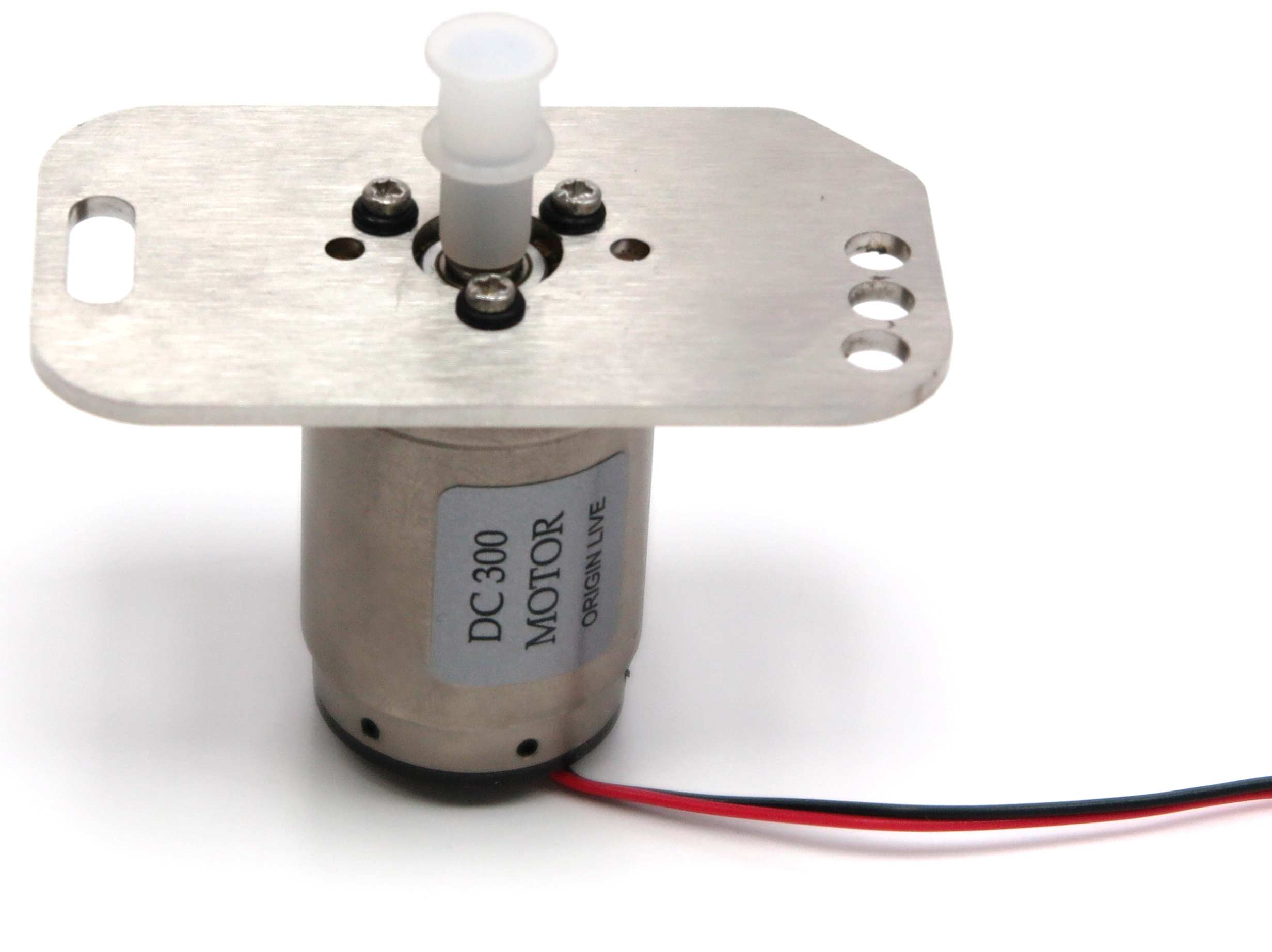

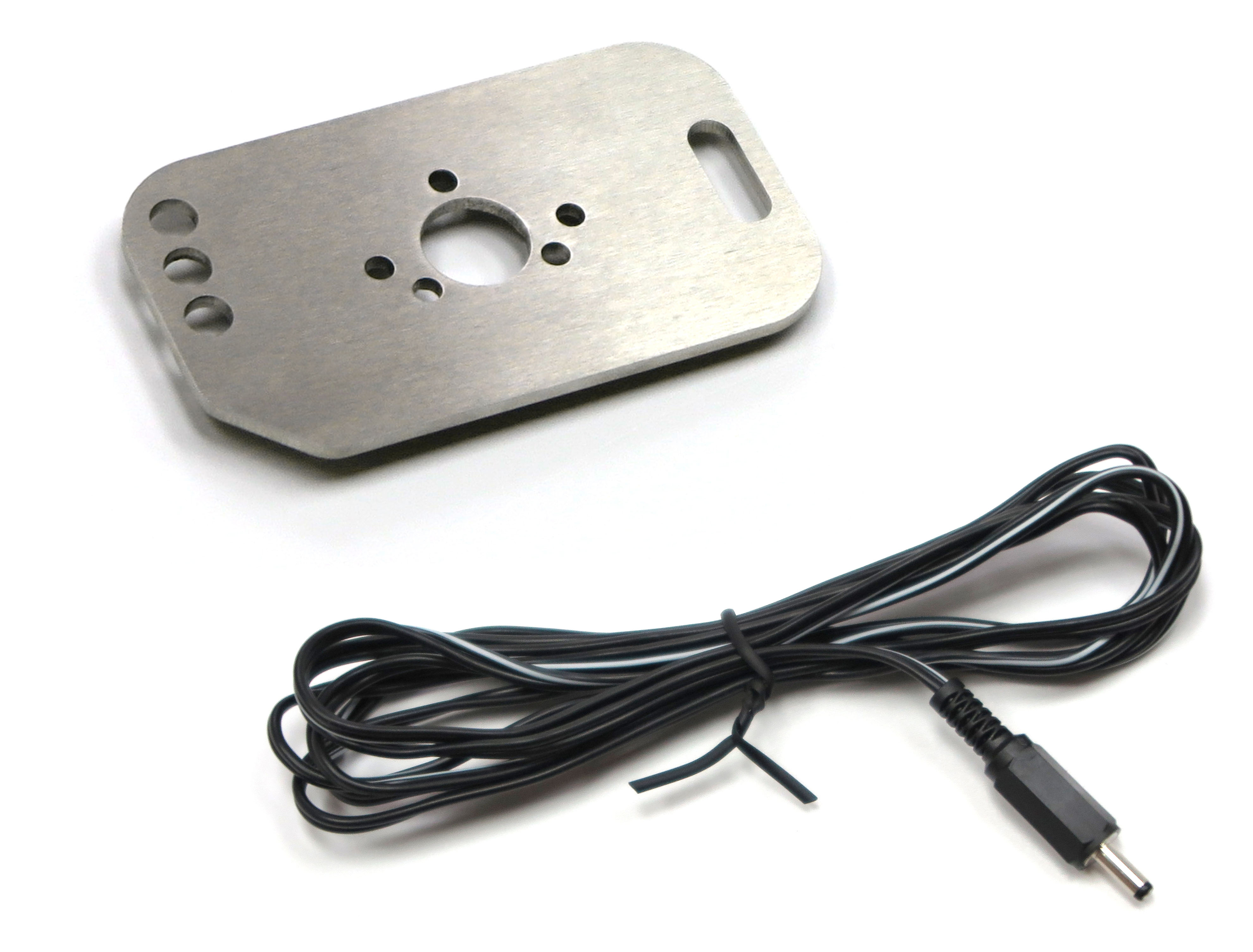

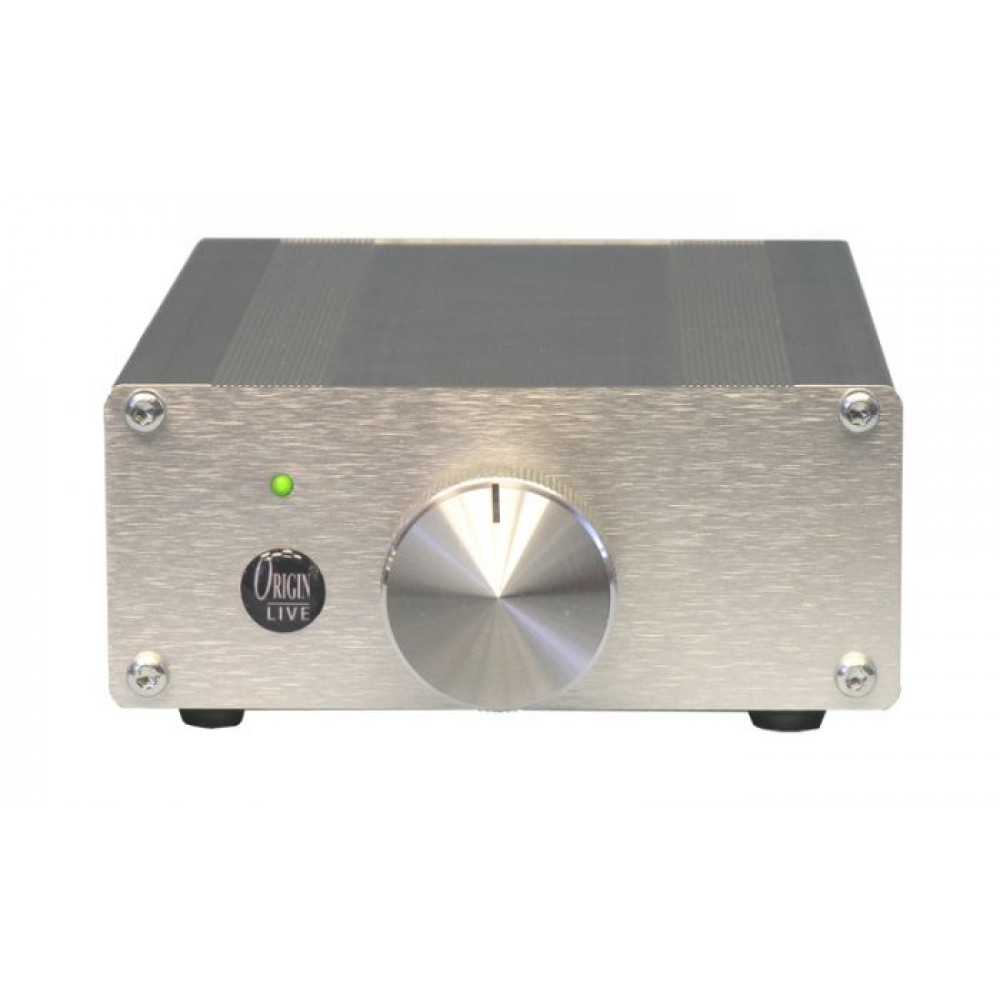

Speed Control BoxMains Transformer DC Motor & PulleyMounting Plate & Lead

Speed Control BoxMains Transformer DC Motor & PulleyMounting Plate & Lead

* A strobe card is also included for easy and accurate speed setting.* The speed setting for 33 and 45rpm is adaptable for all turntables because the control box has infinitely adjustable speed setting capability.

The Most Important Part of Your DeckThe fundamental task of your record player is to keep your platter spinning at an even speed.

To achieve the best possible sound, you need the best possible motor. Our low vibration, Ironless cores outperform outdated motors in older decks.

Electronic Expertise Mechanically, our kits are superb, and easy to operate.The front switch which has 3 positions: Off / 33rpm / 45rpm. You can precisely set the speed for your particular turntable using infinitely adjustable speed trimmers in the rear panel.

What separates the Origin Live Motor Kit from others is a focus on electronics. Years of research have been made in order to offer a Motor Kit manufactured with the expertise which turntables deserve.

More performance than price Good DC motor kits always outperform AC kits, ours outperform kits that are five times the price.Owners of every kind of different deck have reported outstanding results, and you are welcome to test the kit for yourself.

Universal The kit is adaptable, our three different types of transformer will cater for US, Far East, Europe or UK, we will make sure you get the right kit for your country.

Recommendations“nothing can prepare you for the total shock of going DC, in a word gobsmacking… There are details in recordings that I never imagined being present, there is tuneful subsonic bass, and heights that were previously unscaled, the whole music experience has taken on a new meaning, my humble Systemdek record player competes and in many cases far outperforms some of the dearest and best engineered record decks ever conceived.”

Common Ground Magazine

“this is an effective and substantial upgrade that rejuvenates a classic and well respected turntable (Linn LP12) – comes highly recommended”

Hi-Fi World

“Seriously, this is one of the best upgrades I have ever heard” Read More > Michael Knight “I’ve been listening to the DC motor kit for about two weeks. Wow! The degree of improvement on the Valhalla’d table is nothing short of astounding. The Linn bearing and sub chassis design, as well as the arm and cartridge, are performing at their full potential now. Gone is the ‘dry’ character, and the naturalness, detail and dynamics just pour forth. ” J. Schaefer, USA

DC Motor kitFor full description on what makes this dc motor kit so effective please see "Motor Kit Overview" Scroll down to select options

Complete DC turntable Motor and power supply kitsThe Motor kit upgrade comes complete with everything you need which includes Motor, mounting plate, pulley,

Electronic switch box, all leads and connectors, Wall wart plug, strobe card for easy, accurate speed setting and instructions.

No soldering is required - Details of these items are found in "Motor Kit Overview". When you order the motor kit we ensure that you are given the correct transformer for the mains electrical supply of your country unless you specify otherwise in an email to us.

We often get asked whether the kit is easy to fit to a specific deck.

Please bear in mind there are well over 1000 turntable models and we do not have a detailed knowledge of them all.

here are specific examples of motor fitting in the list of decks fitted with the kit.

If your deck is not listed, please assume we have no knowledge of its details so asking us will not help.

General guidance notes on fitting dc motor kits are provided on the web site.

For full quote, including export price (if applicable) and carriage, please go through the online ordering process.

This will deduct vat if applicable and quote carriage once you have entered your address details.

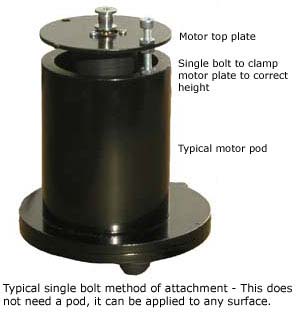

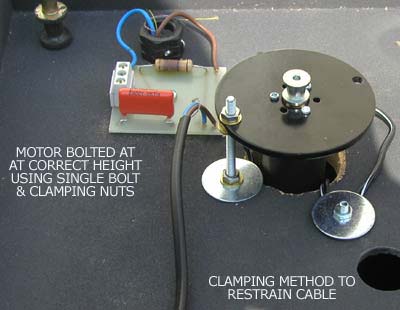

Record Player Motor and Power Supply general fitting methodsOverview of fitting the Record Player motor to your deck Guidance notes are supplied with the kits.

These additional notes are provided to overcome issues that may arise on individual decks. Sometimes the depth of a record player motor means that a deck needs taller feet to lift it clear of the surface on which it stands. Sometimes a hole needs to be cut in the deck baseboard to allow the motor to be fitted. A hole saw mounted on a drill is the best tool for the job (see hole cutting tools.) Alternatively the baseboard can be left off altogether as the voltages are no longer dangerous (12V max). Leaving off the baseboard will also improve the sound of the deck due to reduced resonance.

Record Player Motor Dimensions

Fitting the motor to your record player is all you need worry about as the remainder the kit is plug and play. The dimensions of the motors and their mounting plates are described as follows which may help you to work out how best to fit them. DC100 motor included as standard with every motor kit – body is 29mm diameter and 46mm long.

Record Player Motor Mounting Plates

We offer 3 sizes of motor mounting plate which gives you more flexibility. Normaly you will receive the correct plate for your particular deck as we know the best answer for the more popular record players. The plates are listed below

A rectangular mounting plate is fitted to motor as standard. Dimensions 70mm x 40mm x 2mm with mounting holes spaced 60mm apart.

Circular plate 65mm in diameter with mounting holes spaced 57mm apart is available on special request.

Small round motor plate 45mm diameter with notches for screws (bolts) at 42mm pitch diameter – ideal in pods like the Michell Gyrodek and Orb.

Available by special request.

Only one mounting hole need be used to fit the first 2 motor plates to a deck.

The plate may then be swivelled to set belt tension.

Plinths With Thick Top Plates Sometimes the motor plate must be mounted on the top of a thick MDF top plate in a way that would add too much height. In such cases, a “milling machine” attachment in a pillar drill may be used to cut away the MDF to the correct depth and allow the motor top plate to sink into it. Alternatively a router or sharp chisel may be used.

Methods Of Fitting The Motor These can vary from screwing it on using the tapped holes in the mounting plate to wedging it in position with pieces of hard foam – the motors run cold so there is no overheating problem. Note that the motor sounds best when the top plate is mounted with a single bolt. This allows easy adjustment of belt tension by simply swivelling the whole assembly. It also gives considerable scope for setting the height of the motor using a single machine screw and nuts: the nuts can be used to clamp the motor at any height along the machine screw length.

Motors With Pods For turntables with pods which house the old motor you can adapt the pod to house the new motor – We supply a circular motor top plate for these applications which means that after unbolting the pod’s existing top plate, the Origin Live motor top plate can usually be bolted to the pod using one of the redundant tapped holes – the new DC motor top plate only needs to be fastened using one bolt. This method is not always possible and so alternative methods are to get a machine shop to tailor your old pod to fit the OL DC motor – it may need recessing to get sufficient pulley height – some people give up at this point wondering if it’s worth the trouble but anyone who ever just gets up a rough working set up to see what the new motor sounds like is immediately convinced to go ahead. One last method is simply to pack the motor into the pod by wedging it in position using pieces of hard foam, rubber, Plasticine, blutak or hot melt glue – crude though this may be it works and as the motor runs cold there is no problem on that front.

Belt Length Belts are measured by their circumference in mm. There are two ways of doing this:

Thread length. Put a length of thread round the belt path i.e. the motor pulley and Sub-platter, mark it and then measure the length.

Actual length. Take the old belt. Measure the length of the belt pulled (without stretching) straight and then double the figure.

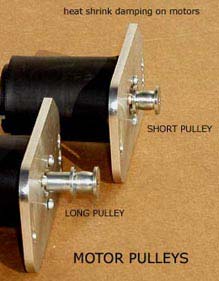

Pulley Choice

The centre of a flat belt rides on the crown of the pulley (the crown is the fattest part of the curved section of the pulley).Round belts ride in the top or bottom notch of the pulley. On the Origin Live “short” pulley the distance from the top surface of the motor plate to the crown is 6mm.

We supply a “long” pulley for use with the Linn LP12 and most other decks. In this case the distance from top of the motor plate to crown is 14mm.

The motor plate is normaly 1.5mm thick. Pulleys are a special high grip white plastic not the aluminium type shown in the photo.

They are also precision bored for smoothest possible running. We stock various pulleys which are press fitted to the motors – if you have the wrong type of pulley for your deck DO NOT TRY TO REMOVE THE PULLEY or you will probably wreck an expensive motor.

The motor should be returned to us complete with pulley and we will change it over. “Short pulley” 8mm diameter at crown 11mm dia overall is useful for decks where the motor is mounted close to the height of the top of the plinth. “Long pulley” is useful for decks where the motor is mounted under a thin top plate e.g. the Linn LP12

The pulleys are designed to run with flat and round belts so there is no need to specify a different pulley for any type of belt (round belts ride in the top or bottom rim recess).

All operating voltage ranges quoted on this page assume the DC100 motor is to be installed. If you order the DC 200 motor the voltage range may need to change – we will provide the correct switching box. The lowest operating voltage of a switch box is always noted on the rear of the switching box.

Note: the photos below are a representative likeness only

Will the Motor Kit fit your Record Player?

Will the Motor Kit fit your Record Player?You may want to ask if the motor kit will fit your particular deck.

The answer 98% of the time is yes but we can’t always provide detailed fitting instructions for well over 3000 different turntable models.

There is help and specific examples of motor fitting in the list of decks below. For all others see the link General fitting guidance > If your deck is not listed, please do not ask as we have no knowledge of its details. The answer is to read General fitting guidance notes and maybe find a similar deck to yours using the list below as a source of examples and ideas. Almost Ceratin to Fit: Rest assured, the motor will almost certainly fit your deck, which is why we offer a money back gaurantee should you run into difficulties. It’s much easier to see how the motor can be fitted once you have it in your hands. The guarantee makes it possible for you to assess things easily, safe in the knowledge that you can return it within 3 weeks or so for a full refund if the fitting is non viable. For a full quote and to order: . The fitting notes below for specific decks: are for guidance only. We do not claim 100% accuracy due to differences between models within each manufacturer’s range. Two heights of pulley are available for use with different decks. Both pulleys suit flat and round belts. The pulleys are described as “short”and “long”. The default choice which fits most decks is the long pulley but when you order, please specify your turntable and we will supply the right pulley for it.

Acoustic Research Tall pulley & 2.5mm nut, no motor plate / belt runs on normal sub-platter. The motor modification has been successfully fitted to Acoustic Research turntables as a straight-forward drop in replacement for the original AC motor. The Acoustic Research Legend needs the motor to be moved and needs a 603mm circumference belt. Acoustic Research Motor & Power Supply Kit Fitting Instructions Alpheson Tall pulley / normal dia sub-platter. This modification has been carried out successfully on a number of Alphesons. The Alpheson Sonata has 2 motors but this is not a problem – you can either replace both motors with ours or use a single motor and a shorter belt. Most users have gone for the 2 motor option which costs an additional 90Ε inc VAT.

General Fitting Methods Avid Tall pulley / belt runs a normal sub-platter – comes with small round mounting plate. Avid Ingenium is easy to fit using a small round mounting plate and tall pulley. Avid Ingenium Motor & Power Supply Kit Fitting Instructions

Ariston Tall pulley / belt runs on normal sub-platter. The motor modification has been successfully carried out on a number of Aristons. The motor is a drop in replacement for the original AC motor

General Fitting Methods Audio Innovations Tall pulley / belt runs on normal sub-platter. The budget Audio Innovations decks (not the Voyds) are modelled on the Systemdek design. The motor modification has been successfully carried out on a number of Systemdeks. The motor is a simple drop in replacement for the original AC motor.

General Fitting Methods Avondale Audio Short pulley / normal diameter sub-platter. The modification has been carried out successfully on the Avondale Audio Genesis. The Genesis has 2 motors but this is not a problem – you can either replace both motors with ours or use a single motor and a shorter belt. Most users have gone for the 2 motor option which costs an additional 90Ε inc VAT. Our motor plate is mounted on the top of the plinth.

General Fitting Methods Bluenote Large diameter pulley / belt runs on rim of platter. We do not know of anyone who has modified a Bluenote yet, but fitting should be simple.

General Fitting Methods Clearaudio 3 Motors fitted to DIY copy of the Clearaudio reference.

General Fitting Methods CS Products Short pulley / Motor on round plate 60mm spaced holes / 0.8 to 2.1V minimum Voltage range for DC100 / small sub-platter. 1 off M4 x 55mm machine bolt plus 3 off 25 od large repair washers 4 off M4 nuts and 3 off M4 brass washers 1 off M4 x 20mm Allen bolt. The motor modification has been successfully fitted to a number of QLS decks and is a straight-forward fitting job. The existing motor plate is replaced by an Origin Live motor plate and mounted level with the top of the turntable plinth. The MDF baseboard needs the motor hole enlarging to allow the motor to protrude from the bottom of the deck – it also needs a 1 x 4.5mm hole drilled to re-site the motor plate support bolt. CS Products Motor & Power Supply Kit Fitting Instructions

DNM Short pulley / round motor plate 60 spaced holes / round belt runs on normal diameter sub-platter. The motor can be substituted for the DNM using our round mounting plate.

General Fitting Methods Garrard It is not possible to fit an Origin Live Motor Kit to direct-drive models.

Kuzma (stabi) Short pulley / Motor on round plate 60mm spaced holes / flat belt on normal dia sub-platter – 3 cork feet. The motor modification can be successfully fitted to the Kuzma decks and is a very straight-forward fitting job of bolting the new motor into the circular cut out using existing bolts and holes – no cutting etc is required. The existing motor plate is replaced by a round Origin Live motor plate Kuzma Stabi Motor & Power Supply Kit

Fitting Instructions Linn Sondek LP12, Axis Tall pulley / belt runs on normal sub-platter. The motor mod has been successfully fitted to a large number of Linn’s as a straight-forward drop in replacement for the old AC motor. The LP12 is a very easy to fit 15 minute job but the Axis needs a little commitment. Over 4 reviewers have fitted this modification to their LP12’s. Linn LP12 Motor & Power Supply Kit Fitting

Instructions Logic Tall pulley / belt runs on normal sub-platter. The motor modification has been successfully fitted to the Logic deck as a straight-forward drop in replacement for the original AC motor.

General Fitting Methods Manticore, Mantra, Magician, Majestic Tall pulley / belt runs on normal sub-platter. The motor modification has been successfully fitted to the Manticore decks (Magician & Mantra) as a straight-forward drop in replacement for the original AC motor.

General Fitting Methods Also see Rega notes: Rega Motor & Power Supply Upgrade Kit Fitting Instructions Music Hall Similar to Rega – see Rega notes. Rega Motor and Power Supply Upgrade Kit Fitting Instructions

Michell: Synchro, Odyssey, Gyrodeck, Orbe Tall pulley / belt runs on outside of platter / circular motor plate 50mm dia. For Michell decks with standalone pods it is possible to fit our DC motor inside the pod. Michell Odyssey needs the 65mm diameter round plate (included with kit). Michell Micro: The motor mod has been successfully fitted to the Michell Micro decks as a straight-forward drop in replacement for the old AC motor. Michell Synchro Power Supply Kit Fitting Instructions Michell Gyrodek Power Supply Kit Fitting Instructions Michell Orbe Power Supply

Kit Fitting Instructions Moth Same as Rega – see Rega notes. Rega Motor and Power Supply Kit Fitting Instructions NAD Same as Rega – see Rega notes. Rega Motor and Power Supply

Kit Fitting Instructions Nottingham Analogue Tall pulley / belt runs on outside of platter. Motor housed in a pod can be substituted with our DC motor using the methods here. Nottingham Analogue Motor & Power Supply

Kit Fitting Instructions Opus Tall pulley / belt runs on outside of platter. In spite of being a rare beast this deck has successfully been fitted with the Origin Live advanced DC motor kit. Motor housed in a pod can be substituted with our DC motor.

General Fitting Methods Oracle Delphi Long pulley / belt runs on medium sub-platter. The motor mod has been successfully fitted to a good number of Oracles using the methods here. Oracle Delphi Motor & Power Supply Kit Fitting Instructions Origin Live For Origin Live ultra and classic turntables, use a short pulley on a small round motor plate. For All other decks a tall pulley is used. The motor kits are easily fitted to Origin Live turntables of all ages.

Pink Triangle: Export, Little Pink Thing (LPT), PT Too, Anniversary Long pulley / belt runs on normal sub-platter. The motor modification has been successfully fitted to a good number of Pink Triangles (Little Pink thing, PT-TOO, Anniversary, export etc) as a drop in replacement for the original AC motor. It can be fitted using methods described at bottom of this page. Although Pink Triangles have fine sound quality the power supplies are notoriously prone to breakdown – this long term problem is solved by the Origin Live DC motor kit which has a proven track record for reliability. Export PT – if a hole is bored in the top plate for the motor the short pulley is fine. (Pulley top needs to be 24mm above motor plate if special pulley is machined). Anniversary PT – short pulley and 423 diameter circumference belt. LPT (Little Pink Thing) – Parts we provide: short pulley, M5 X 80mm machine screw bolt, round plate 65 diameter with 5mm diameter fitting hole. 2 repair washers 25mm diameter, 3 off M5 nuts, 3 off M5 washers, 1 off M6 washer, 1 off No 6 x 3/4″ cross head screw, 1 off cable clip. Pink Triangle Little Pink Thing(LPT) Motor & Power Supply Kit Fitting Instructions Pink Triangle PT Too Motor & Power Supply Kit Fitting Instuctions Pink Triangle Anniversary Motor & Power Supply Kit Fitting Instructions

Pro-Ject: PR4, Classic PR4 – long pulley, Classic – long pulley. Pro-Ject Motor & Power Supply

Kit Fitting Instructions General Fitting Methods Rega Short pulley / 0.8 to 1.5V minimum Voltage range / small dia sub-platter, 2 off M2 x 5mm cross hd screw & M3 washers The motor modification has been successfully fitted to a good number of Rega decks as a straight-forward drop in replacement for the original AC motor. Rega Motor & Power Supply

Kit Fitting Instructions Roksan Short pulley set high / Special Roksan motor plate / belt runs on normal sub-platter – best to get upgrade belt at 555mm circumference. The motor mod has been successfully fitted to a good number of Roksan turntables as a straight-forward drop in replacement for the original AC motor. You need to remove all the original motor mounting and then screw the new motor plate to the top of the plinth using a single screw, it’s very easy to fit. The plate is fitted using one screw into the top of the plinth such that the triangular cut off from the plate misses the platter rim.

General Fitting Methods Roksan Radius 5 Tall pulley / belt runs on outside of platter. Has been successfully fitted to VPI decks. Old motor can be substituted with our DC motor kit. Roksan Turntable Motor & Power Supply

Kit Fitting Instruction Townsend Rock Short pulley / 0.9 to 2.4V minimum Voltage – belt runs on small diameter sub-platter. A good number of rock models have been modified with great success. The new motor is usually attached to the top plate of the rock although on some models you may have to cut some of it away. Alternatively you can mount the motor in a large lump of Blu Tack pressed into the empty space left after the removal of the old motor.

Townsend Rock Motor & Power Supply Kit Fitting Instructions SME Tall pulley / belt runs on outside of platter. Not attempted yet – but a straight-forward upgrade is anticipated.

General Fitting Methods Strathclyde Transcription Developments Tall pulley / belt runs on normal sub-platter. The motor modification has been successfully carried out on a number of STD turntables. The motor is a drop in replacement for the original AC motor and very easy to fit using the fitting instructions.

General Fitting Methods Systemdek IIX 900 Long pulley / belt runs on normal sub-platter. The motor mod has been successfully carried out on a number of Systemdek turntables. The motor is a drop in replacement for the old AC motor and very easy to fit using the methods described here.. The motor is usually screwed to the top of the plinth. Systemdek IIX 900 Motor & Power Supply

Kit Fitting Instructions Technics This deck can only be upgraded to our DC kit by changing all working parts using the Origin Live kit of parts as per the review published on our web site under “turntable kits” – this is a fairly advanced project and is only available direct from Origin Live. Specification for motor kit is same as Origin Live.

General Fitting Methods Teres No motor or pulley required – use Teres existing motor & pulley / 2.4 to 4.5V minimum Voltage. This deck can be significantly upgraded by simply substituting the power supply with the Origin Live advanced or ultra switching box and optional upgrade transformer. It does not need the Origin Live motor as it already possesses a high grade motor – this makes fitting very easy as it is just a question of wiring in the motor.

General Fitting Methods Thorens Tall pulley / belt runs on normal sub-platter. The motor modification has been successfully carried out on a number of Thorens turntables. The motor is a drop in replacement for the original AC motor and very easy to fit – See Linn LP12 for guidance notes as this is very similar to the Thorens. Fits all models except the 124.

General Fitting Methods Transrotor Leonardo Short pulley fitted inside Origin Live 64mm dia pod 58mm to top of pod/ 0.8 to 1.4V minimum voltage range / belt runs on very small sub-platter. The motor mod has been successfully fitted to a Transrotor turntable. The motor needs to be mounted in a pod. Transrotor Leonardo Motor & Power Supply

Fitting Methods Voyd: Valdi, Reference Tall pulley / normal dia sub-platter. This modification has been carried out successfully on both the Voyd Valdi and Voyd Reference. The Valdi has 2 motors and the Reference 3 but this is not a problem – you can either replace the motors with ours or use a single motor and a shorter belt. Most users have gone for the 2 or 3 motor option which costs an additional 90Εinc VAT or 190Ε for an extra 2 motors.

General Fitting Methods VPI Tall pulley / belt runs on outside of platter. Has been successfully fitted to VPI decks – original motor can be substituted with our DC motor.

VPI HW19 series just set the motor in the hole in the plinth that the VPI pulley normally sticks up through and then slip on the OL pulley.

General Fitting Methods Walker Tall / belt runs on normal diameter sub-platter. It is easy to fit the DC motor to this classic deck. Comments on this upgrade. Walker Motor & Power Supply

Kit Fitting Review General Fitting Methods Well Tempered Tall pulley / belt runs on outside of platter. Has been successfully fitted to well tempered decks. Motor needs to be remounted in the Well Tempered pod. Well Tempered Turntable Motor & Power Supply

Kit Fitting Instructions Wilson Benech Short pulley / belt runs on normal sub-platter. Not straight-forward but possible – a trial is underway. Motor can be fitted using methods described here but the motor pod will be visually impacted. Wilson Benesch Motor & Power Supply Fitting Instructions

Acoustic Research Yes- Alpheson Yes

- Avid Yes

- Ariston Yes

- Audio Innovations Yes

- Avondale Audio Yes

- Bluenote Yes

- Clear Audio Yes

- CS Products Yes

- DNM Yes

- Garrard No

- Kuzma Stabi Yes

- Linn Sondek LP12 Axis Yes

- Logic Yes

- Manticore Mantra Yes

- Manticore Magician Yes

- Manticore Majestic Yes

- Music Hall Yes

- Michell Syncro Yes

- Michell Odessy Yes

- Michell Gyrodeck Yes

- Michell Orbe Yes

- Moth Yes

- NAD Yes

- Nottingham Analogue Yes

- Opus Yes

- Oracle Delphi Yes

- Origin Live Yes

- Pink Triangle Export Yes

- Pink Triangle Little Pink Thing Yes

- Pink Triangle PT Too Yes

- Pink Triangle Anniversary Yes

- Pro-Ject PR4 Yes

- Pro-Ject Classic Yes

- Rega Yes

- Roksan Yes

- Roksan Radius 5 Yes

- Townsend Rock Yes

- SME Yes

- Strathclyde Transcription Developments Yes

- Technics Yes

- Teres Yes

- Thorens Yes

- Transrotor Leonardo Yes

- Voyd Valdi Yes

- Voyd Reference Yes

- VPI Yes Walker Yes

- Well Tempered Yes

- Wilson Benech Yes

*please add on comments for what turntable is your order

Free ship cost in Europe for order up to 500€ (except speakers)

Free ship cost Worldwide for order up to 2000€ (except speakers)

-378x378.jpeg)